Epoxy floors are an increasingly popular choice among commercial and industrial properties, as they're durable, easy to maintain, cost-efficient and help reduce maintenance expenses over time. Plus, epoxy can even save money in terms of reduced maintenance expenses!

These floors feature epoxy floor coatings that are resistant to chemicals, heat, and oil damage and slip-resistance when added with silica sand additive.

Easy to clean

epoxy floors are highly resilient and can withstand years of wear and tear without suffering much in terms of maintenance needs, yet still require routine care to keep looking their best. Routine daily sweeping and mopping along with periodic mopping will do just fine in maintaining them; frequency of scrubbing depends on how often oil or chemical spills occur on your flooring surface - in areas that experience frequent oil spills more often will need more regular scrubbing to remain looking great.

In general, soft deck brushes or kitchen sponges should be sufficient to remove stains that develop on an epoxy coating surface. Harsh chemicals and abrasive scrubbing pads may damage this finish; for persistent spots try mixing one part simple green or ammonia with 10 parts water; alternatively soak your area in concrete degreaser before scrubbing with a nylon brush.

While scrubbing the floor, it's also important to inspect for large scratches or gouges in its surface. Any of these should be addressed immediately so they do not worsen over time, leaving mold growth which poses health hazards in addition to slippery and hazardous floors that must remain clean and safe for everyone who uses the area.

Durable

Epoxy flooring is an extremely resilient material that can withstand heavy traffic and impact without succumbing to dent and scratch damage, yet still resist dents and scratches. However, for optimal performance it must be regularly cleaned and damaged addressed promptly - otherwise its lifespan will shorten significantly and incur costly repairs or replacement costs down the line.

Proper maintenance of epoxy floors is key to prolonging their beauty and prolonging their longevity. Sweeping and vacuuming the floor on a regular basis to remove dirt, dust, debris and particles that could potentially harm its coating; soft brushes or microfiber mops work best because these don't scratch up its surface like some tools do. Furthermore, it is crucial that pH neutral and nonabrasive cleaning products be used.

Professional maintenance should also be scheduled periodically to reseal and repair cracks in epoxy coatings, helping ensure your floors are hygienic and safe for commercial or community spaces, minimizing risks like the buildup of harmful bacteria and prevent the formation of scuffs and scratches that compromise its aesthetic appeal. Furthermore, regular inspections and maintenance can help stay compliant with health and safety regulations for lasting positive relationships in your industry.

Versatile

Epoxy flooring provides an abundance of colors that can complement the aesthetics of your brand or add an eye-catching visual impact, as well as customizable coating options to meet individual needs and textured coatings can be customized according to customer preferences. Furthermore, metallic pigments can add an elegant glow that makes this flooring ideal for retail spaces, showrooms and even automotive garages.

Epoxy flooring boasts impressive chemical resistance. It can withstand spills and splashes of harsh chemicals like cleaners, gas, oil and transmission fluid that normally damage traditional floor materials, while it also stands up well to thermal shock, sudden impacts and abrasion.

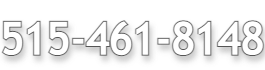

As Epoxy Flooring IOWA protect and preserve the appearance of epoxy flooring, it's vital that a daily maintenance schedule be implemented. This should include sweeping and mopping of the floor as well as refraining from dragging heavy objects on it as this could scratch its coating or lead to gouges and cuts in its coating, along with cleaning up spills promptly to prevent chemical etching of its coating and ensure safe conditions for employees and customers.

Installing your epoxy floor by professionals who understand surface preparation will also ensure its long-term beauty and maintain its beauty over time. Professional installation ensures less wear and tear for greater longevity of its aesthetic appeal over time.

Affordable

Epoxy floors are cost-effective, durable and resistant to cracks and stains, so they last a long time while still looking their best. Recoating or retexturizing them when damage occurs means no complete replacement needs to be performed when scuffs occur; with clear epoxy coatings you have options of adding decorative flakes or metallic pigments for a unique river rock look! Additionally, customized quartz aggregate blends or stones such as pebbles may also add personality.

Before applying epoxy, floors must first be degreased and cleaned of dirt, debris, moisture and any potential mold growth, with surface cracks filled to avoid mold growth and any larger than 1/8" cracks being repaired to avoid showing through. Professionals usually fill these larger cracks using an acrylic or polyurethane caulk that's forced into each one with an putty knife; this step typically costs around $10 per square foot.

To reduce dirt accumulation on an epoxy garage floor, adding grit or aluminum oxide additive to the clear coating can help. This will keep the surface free of debris that might otherwise collect, while regular vacuuming also can remove trapped dirt and sand particles. Furthermore, protective pads under heavy machinery and furniture will evenly distribute weight distribution and minimize potential damage.